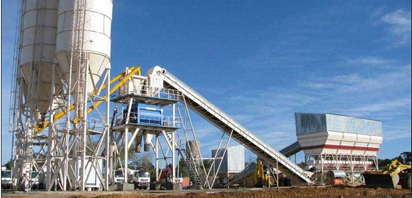

For more concrete batch Plant technical documents, Download free in PDF form !!

concrete batching plant--Cement Silo

Cement silo is mainly used in commercial concrete batching plant and engineering concrete batching plant. Cement silo (cement tank) is suitable for storing grain, cement, fly ash and other bulk materials. The tank is equipped with material level control system which can display the level of the material. In a concrete batching plant, cement silo (cement tank) is mainly used for storing raw materials of producing concrete such as cement, fly ash etc.

cement silo

The main components of cement silo (cement tank) are: steel structure of the silo body, ladder, guard bar, feeding tube, dust collector, safety pressure valve, level indicator, discharge valve.

Cement silo (cement tank) is in cylindrical shape, in the bottom of the silo, there are four supporting legs. The whole body of a cement silo is welded with steel.

1. When using a cement silo (cement tank), operators should hoist it with special crane, and then place it on prefabricated concrete foundation. After that, they should check whether the cement silo (cement tank) is perpendicular to the horizontal plane, and make sure the bottom base is welded firmly with the embedded foundation parts.

2. After the storage silo fixed and the cement are transported to the site by concrete mixer truck, the operator should connect the concrete mixer truck’s transmission lines and cement silo (cement tank) feeding tube. The gas pressure of concrete mixer truck will push the cement into the cement silo (cement tank).

3. In the process of transporting cement to the inside of the storage bin, the operator must make sure the vibration motor of dust collector is working and make sure the vibration can shake off the dust attached on the bag of dust collector, in case the bag are blocked.

4. If the bag were blocked, pressure inside the silo will exceed the safety pressure, safety pressure valve will open to release pressure and prevent explosion accidents.

5. Operators can judge whether the silo is full or lacking of material through the level indicator.

6. When you need to discharge, open the manual discharge valve at the bottom, and then the cement will be conveyed through the screw conveyor.

haomei Machinery provides bolted cement silo and welded cement silo with capacities range from 30t, 50t, 60t, 80t, 100t, 200t to 300t. Welcome to consult us.

Cement silos are on-site storage containers used for the storage and distribution of various types of cement mixtures. Silos of this type come in a variety of sizes, making them ideal for use at many kinds of construction sites. A cement silo can be a permanent structure, or a portable model that can be relocated when necessary. Like many other types of silos, the cement silo usually is equipped with some type of blower to help expel the stored contents into a truck or other receptacle.

A cement storage silo can be structured to hold no more than a few tons of dry cement product, or be designed to efficiently hold several hundred tons. Generally, larger silos are permanent structures that cannot be moved. These are likely to be found at concrete plants, where the finished product is stored until it is time for shipment. Many building sites that utilize concrete in the construction process opt for portable cement silos that can be moved around the site as the need arises.

It is not unusual for construction companies to keep several portable cement silos available for different building projects. These simple storage devices can usually be set up in a matter of hours, then dismantled once the project is complete. Storage of the portable cement silo is relatively easy, since the components can be stored in a warehouse until the device is needed at another building site.

Both the permanent and the portable cement silo are usually equipped with some type of blower. The blower makes it easier to expel the product from the silo. Blowers are often driven by electricity, although there are models that rely on propane or even gasoline. Blower equipment with the portable silos takes very little time to set up, and can also be stored easily when not in use.

It is important to note that the materials and the design of a cement silo will vary, depending on the type of cement product that is to be stored in the facility. Not all types of building materials are conducive to keeping all of the various components that go into cement blends from caking or absorbing moisture. For example, a silo that is structured to protect the integrity of soda ash may not work as well with lime. Along with the ingredients of the concrete, the configuration of the cement silo will be slightly different for products that are identified as high performance concrete or self-compacting concrete.